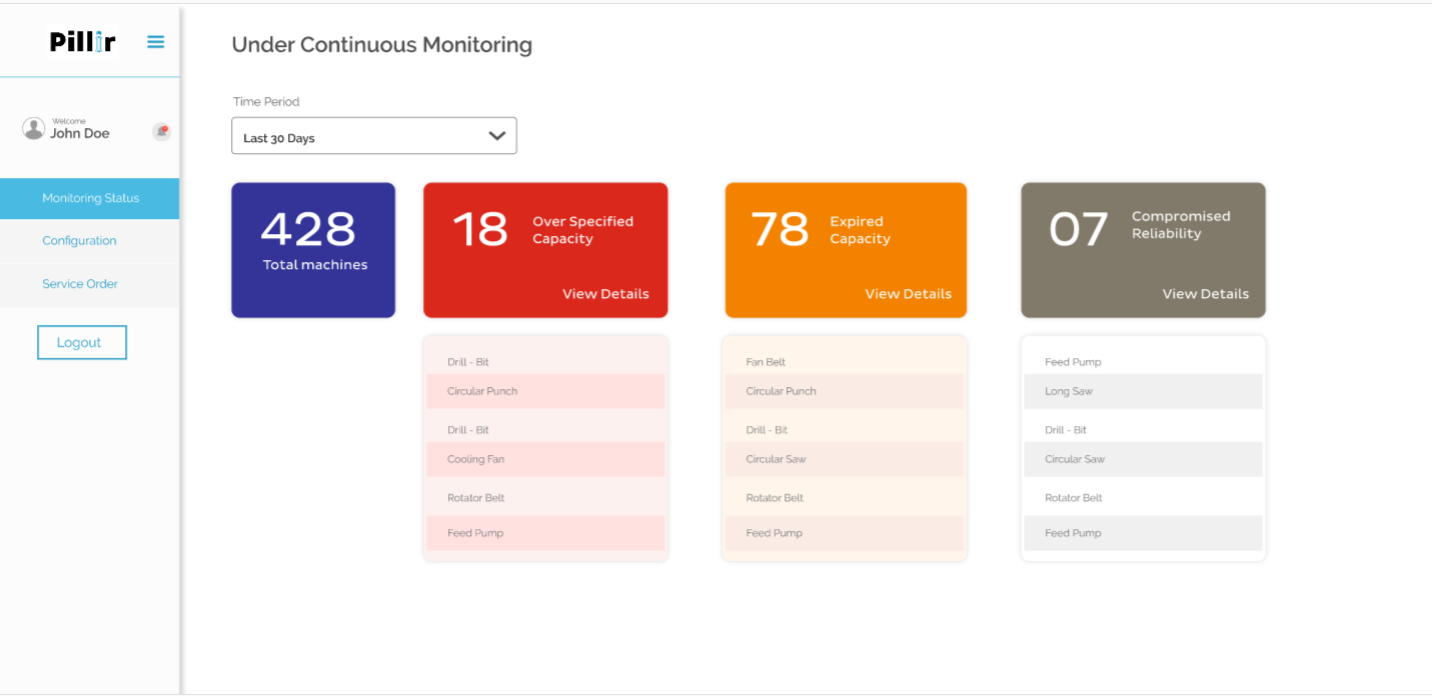

Predict potential breakdown by detecting variances in the operations, assets & equipment & processes. Pillir apps suite analyses real-time data in comparison with historical data to anticipate potential defect before it happens.

Pillir's predictive maintenance suite of apps is designed to help businesses optimize their maintenance operations and reduce downtime. Our suite of apps includes asset health monitoring, predictive maintenance planning, equipment performance analytics, maintenance workforce management, and supplier management. With real-time data from sensors and machine learning algorithms, our suite of apps can predict maintenance requirements, identify opportunities for improvement, and optimize maintenance schedules. Built on the low-code Pillir platform, our suite of apps can be customized to meet specific business needs and integrated with other systems and applications. Contact us today to learn how our predictive maintenance suite of apps can help your business achieve its maintenance goals.

Improve the efficiency and effectiveness of maintenance operations by digitizing predictive maintenance operations. Reduce downtime and prevent equipment failures, resulting in improved equipment reliability and increased productivity.

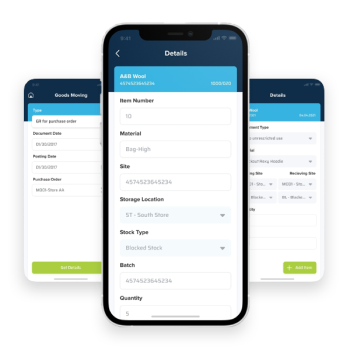

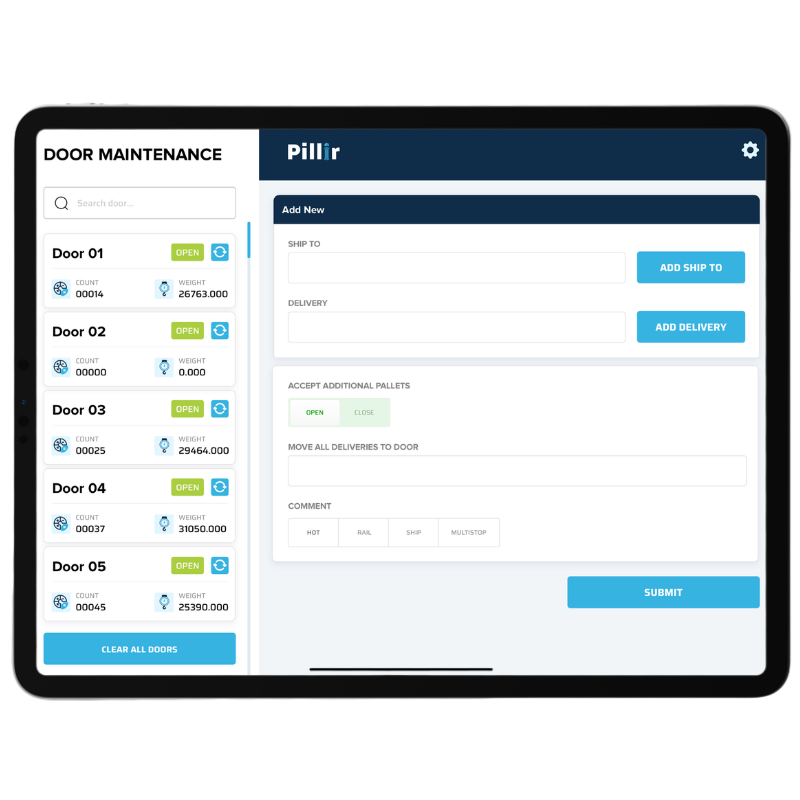

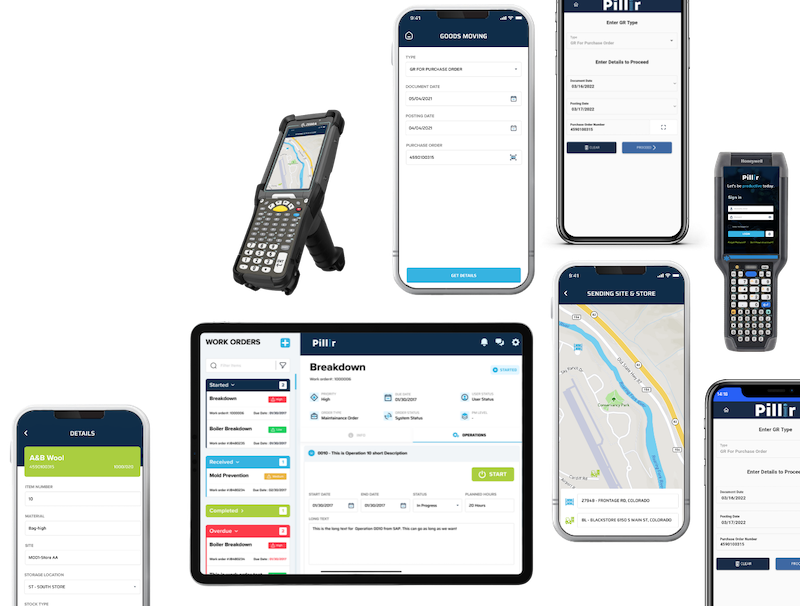

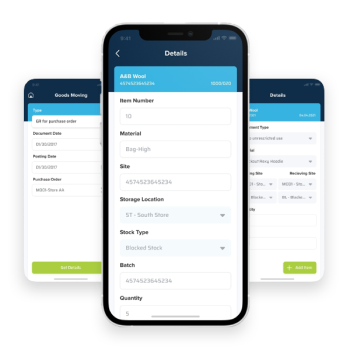

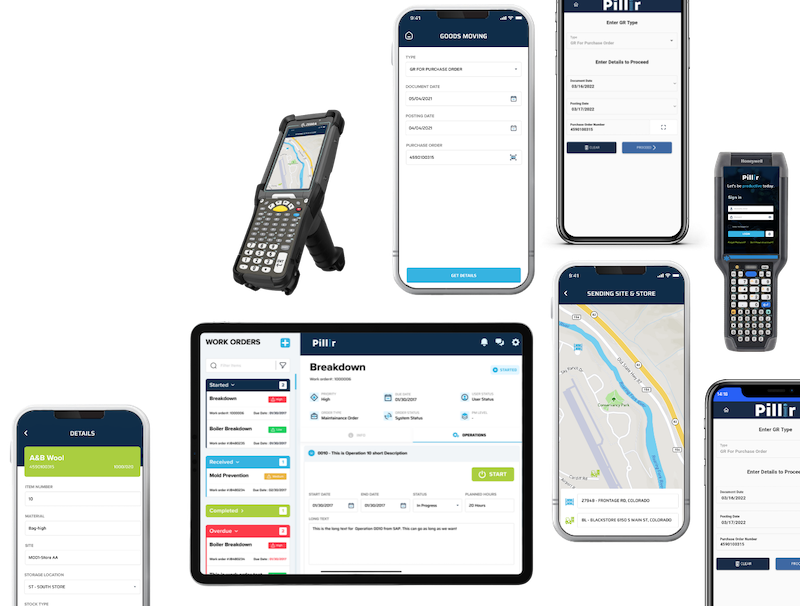

Pillir's predictive maintenance mobile apps also offer features such as work order management, asset tracking, and inventory management, which helps maintenance teams to stay organized and efficient.

Identifies all the preventive maintenance tasks.

Generates schedules to plan and/or execute the preventive maintenance tasks.

Sets SLAs for equipment, assets with appropriate service quality standards and deadlines.

Keeps all required technical & legal documents for equipment and assets easily accessible.

Seamless transition from offline to online mode

Automatic data sync between Pillir platform and mobile device once connected to internet.

Built-in functionality to scan QR codes and Bar codes with devices for faster retrieval of info.

Capture and upload of live images directly to service orders or audits.

Push notifications to the users to whom service orders are assigned.

Provided with extensive ‘Template’ reports.

Dashboard to provide real-time KPI information.

Facility to filter data in multiple ways to generate meaningful reports.

Improve the efficiency and effectiveness of maintenance operations by digitizing predictive maintenance operations. Reduce downtime and prevent equipment failures, resulting in improved equipment reliability and increased productivity.

Pillir's predictive maintenance mobile apps also offer features such as work order management, asset tracking, and inventory management, which helps maintenance teams to stay organized and efficient.

Identifies all the preventive maintenance tasks.

Generates schedules to plan and/or execute the preventive maintenance tasks.

Sets SLAs for equipment, assets with appropriate service quality standards and deadlines.

Keeps all required technical & legal documents for equipment and assets easily accessible.

Seamless transition from offline to online mode

Automatic data sync between Pillir platform and mobile device once connected to internet.

Built-in functionality to scan QR codes and Bar codes with devices for faster retrieval of info.

Capture and upload of live images directly to service orders or audits.

Push notifications to the users to whom service orders are assigned.

Toray struggled with a few roadblocks that were disrupting the customer delivery process in terms of punctuality and budget. Pillir provide a user-centric, customized experience that tightly integrates to SAP and is based on roles and authorizations. Along with the applications streamlining and digitizing the once manual processes, the applications were deployed quickly and with little-to-no programming.

Paul McDevitt

Director of Materials, TPA, Inc.

Dole Packaged Foods was struggling with the manual creation of material master data. Pillir supported the team in designing and developing a user-centric web app that digitized every role and workflow across the entire materials creation process.

GABE DELLEVIGNE

Head of Digital Transformation, Dole

SAP-integrated digitized asset management deployment ready, yet customizable to your company needs.

Use the Pillir Accelerator Goods Movement app for faster fulfillment and lower operational costs to meet today’s labor shortage and supply chain challenges.

Pillir is an edge-first platform that delivers mission-critical workflows on any device—whether you’re running silent sustainment in a forward operating base (tactical edge) or driving productivity on a factory floor (operational edge). By turning SAP, Oracle, and legacy back-ends into AI-powered, role-based apps and agents, Pillir lets your teams simply “tap, ask, done,” online or offline. With built-in security, zero-signal execution, and deployment in weeks rather than quarters, Pillir empowers frontline workers and warfighters alike to move goods, fix gear, and defend our freedoms—no hidden menus, no special training required.