A goods receipt in SAP gives warehouses the tools to receive products, parts, partial assemblies, or raw materials efficiently and effectively. SAP provides logical steps to manage the goods receipt process – and also a way to handle a goods receipt reversal in SAP when necessary.

Several events can necessitate a goods receipt reversal in SAP EWM or other warehouse management solution. For example, a warehouse employee may have entered the wrong quantity or entered the goods received against the wrong purchase order. Or a warehouse team may have discovered that goods are damaged or don’t meet quality standards and decide to return some or all of them.

Steps in Goods Receipt Reversal in SAP

The reverse goods receipt process will vary slightly depending on your system configuration. However, you’ll follow these steps, in general:

- Pull up the purchase order related to the goods receipt that you’ll reverse.

- Find the material document number, then using MIGO, select “return delivery” in the drop-down menu, and click “Ok” for the items you are returning.

- You will need to enter a reason for the goods movement, and you’ll have the option to make notes about why you made the reversal.

- Post or save the information you recorded.

- Next, you can locate goods, issue a return transfer order, and prepare them for return.

SAP goods receipt reversal also gives you the ability to reconcile reverse goods receipt delivery cost when valuated differently in SAP and account for refunds or rebates. If a goods issue has already been executed, a warehouse employee will need to reverse the goods issue and then reverse the goods receipt.

It’s vital for companies to establish policies on how to handle goods receipt reversals. For example, if a system is configured to immediately match the purchase order, goods receipt and invoice and the invoice is paid, the company will need to set policies for how to issue an SAP reverse goods receipt after invoicing.

The Role that People Play

SAP automates much of the data sharing and reconciliation required for goods receipt reversal. However, people are integral to the process. Employees need to address discrepancies, identify damaged or poor quality stock, and enter the appropriate data to initiate the reversal accurately. Paper-based processes aren’t sufficient for managing goods receipt reversal – in fact, they may be the root cause of inaccurate quantities or matching it to the wrong purchase order that made the reversal necessary in the first place. In addition, manually recording data limits visibility and takes more of an employee’s time than with digital processes.

Employees can manage goods receipt reversals – and many other warehouse processes – more effectively with mobile solutions. Moreover, an app designed specifically for goods receipt reversals in SAP will ensure employees follow all company policies and necessary steps to carry out the process effectively.

Developing mobile apps, however, has been a challenge for many warehouses and other SAP users. Solutions such as SAP Fiori may provide some benefit, but they’re difficult to customize if an operation requires more than just changing a field or hiding a screen.

Put Goods Receipt Management in Employees’ Hands

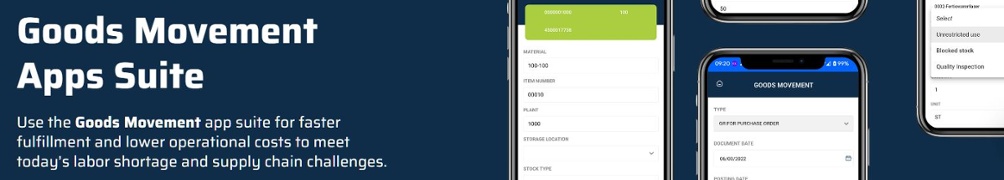

To help warehouses overcome this challenge, Pillir developed its Warehouse Management suite of mobile and web applications. These apps, based on industry best practices, provide all of the functionality you need to run your warehouse efficiently, such as:

- Goods movement and storage bins management

- Physical inventory management, planning and monitoring

- Pick, pack, and ship

- Door, pallet, and delivery maintenance

Employees can use the apps on any mobile, rugged, or RF device out of the box or have Pillir customize them to align with your unique processes, such as following company policies for goods receipt reversal in SAP. Even if you require customizations, the apps still deploy within a few weeks, giving you a quick path to eliminating paper-based manual processes and many of the errors that can lead to the need for goods receipt reversals.

Also, Pillir’s Warehouse Management suite of apps is built on its low-code/no-code platform that uses the EdgeReady Plugin for deep integration with SAP while keeping your SAP core clean. Therefore, there’s no need to build OData connectors for data flow from your mobile apps to your ERP system, whether you’re using SAP ECC or SAP S/4HANA.

Learn more about Goods Receipt Reversal in SAP

Mistakes happen, so it’s necessary to establish policies for managing goods receipt reversals in SAP to correct data entry errors, correct errant shipments, or hold suppliers to high quality standards. Managing goods receipt reversals with mobile solutions is the best way to update data in real time and ensure they’re handled accurately and with no losses.

Learn more about how you can enhance your goods receipt, goods receipt reversal and other warehouse management processes with apps designed for your operation. Try the Goods Movement apps to see for yourself!

Back

Back/Logo%20-%20black%20text%20blue%20pillar%20(large)-1.jpg)